Exactly How to Recognize Common Fixing Problems in Stretch Wrap Machines and When to Look For Expert Help

Stretch Wrap machines are vital for effective packaging procedures. However, they can experience numerous problems that impede efficiency. Operators has to be watchful in acknowledging signs of malfunction, such as irregular movie tension or unusual noises. Understanding these usual repair service problems is essential. Yet, understanding when to seek specialist assistance can make a substantial difference. The nuances of troubleshooting and upkeep are worth discovering even more.

Comprehending the Basics of Stretch Wrap Machines

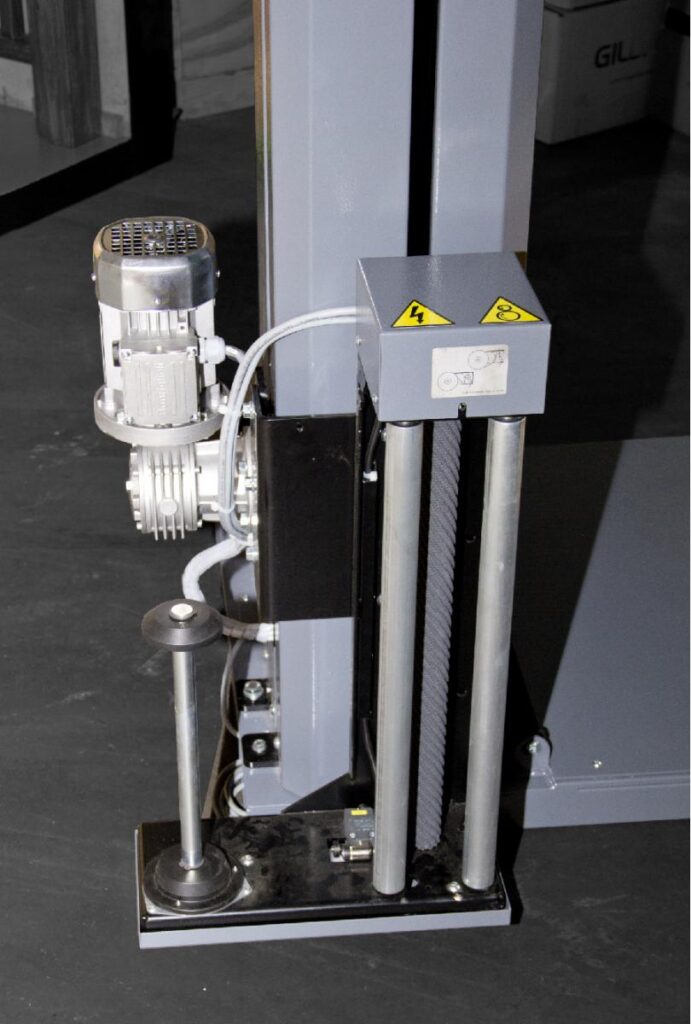

Stretch Wrap makers are crucial devices in the packaging sector, created to securely encapsulate items for storage space and transport. These devices make use of stretch film, which complies with itself, producing a protective and limited layer around things. Usually, they come in various types, consisting of handbook, semi-automatic, and totally automatic designs, dealing with diverse production demands. The operation of a stretch Wrap equipment includes feeding the movie around the item, using stress, and securing the Wrap, making certain that items remain steady during transit.Key components of these machines include the movie turntable, carriage, and control panel, each playing a crucial duty in the covering process. Performance is better improved by adjustable setups that enable users to personalize the tension and variety of wraps. Recognizing these essentials helps operators make best use of the maker's performance, making sure suitable product packaging high quality and lowering the risk of item damages throughout handling or delivery.

Typical Concerns With Stretch Wrap Machines

Product packaging effectiveness can be significantly endangered by common concerns that emerge with stretch Wrap machines. One widespread problem is irregular film tension, which can result in poor load stabilization and increased product damages throughout transport. Furthermore, movie damage frequently happens, disrupting the wrapping process and causing hold-ups in operations. Another concern is the inappropriate alignment of rolls, which can result in uneven covering and wastefulness of materials.Malfunctions in the control board may additionally impede functionality, making it hard to change settings or monitor efficiency. Electrical problems, such as faulty wiring, can better contribute to operational ineffectiveness. Regular upkeep can help alleviate most of these problems, making sure the machine runs smoothly. Acknowledging these typical problems is vital for operators, as prompt treatment can protect against extra costly repair services and significant malfunctions.

Signs Your Stretch Wrap Machine Needs Repair

When a stretch Wrap machine displays unusual sounds throughout operation, it might suggest underlying mechanical problems. Additionally, irregular film stress and frequent downtime can further signal that the equipment requires instant interest. Recognizing these indications early can aid protect against costly repair services and assure peak efficiency.

Uncommon Noises Throughout Procedure

Uncommon sounds throughout operation commonly signal underlying concerns with stretch Wrap equipments that need immediate attention. These noises might consist of grinding, squeaking, or clanking, which can show damage on components such as bearings, gears, or electric motors. It might be having a hard time with imbalance or not enough lubrication if the machine produces unforeseen noises. Ignoring these audio hints can bring about additional damages and pricey repairs. Operators needs to perform routine evaluations to determine and resolve the source of the sound without delay. Consulting the device's manual can give certain standards for upkeep and troubleshooting. If the problem persists after basic checks, looking for specialist assistance is recommended to ensure the device's long life and height performance.

Irregular Film Tension

Irregular film stress can greatly influence the effectiveness of stretch Wrap devices, resulting in poor tons stability and possible product damages. This problem frequently shows up as irregular wraps, where certain locations of the tons are firmly protected while others are loose. Operators may observe that the stretch film is either under-stretched or over-stretched, impacting its ability to adapt to the tons. In addition, there may show up indicators of moving or slippage throughout transport, indicating that the film is not supplying adequate assistance. Such variances can arise from worn-out elements, incorrect calibration, or malfunctioning sensing units. Addressing these issues immediately is crucial to guarantee peak device performance and to stop further problems that can arise from inadequate covering.

Frequent Downtime Issues

Frequent downtime issues can signify that a stretch Wrap device requires urgent fixing. These disruptions often show underlying mechanical failings or system breakdowns. Operators might see enhanced frequency of jams, which interrupt the covering procedure and hinder productivity. Uncommon noises during operation can also act as red flags, suggesting that parts might be misaligned or broken. In addition, inconsistent film application can bring about insufficient tons protection, prompting further functional hold-ups. Neglecting these signs may lead to a lot more severe damages and expensive repairs. It is necessary for operators to check their equipments carefully and address any type of indicators of breakdown promptly, making sure reliable operation and minimizing downtime in the her latest blog long run. Looking for professional aid might be necessary for complicated issues.

Repairing Minor Problems

Repairing minor issues in stretch Wrap equipments needs a methodical strategy to identify and deal with problems effectively. Operators ought to start by examining the power supply and ensuring all connections are safe and secure. If the device does not start, validating the breaker and integrates can frequently disclose straightforward electric issues. stretch wrap machine repair near me.Next, inspecting the stretch Wrap movie for appropriate positioning is vital. Misalignment can result in uneven covering and may need adjustment of the movie rolls. In addition, operators article should check the tension settings; incorrect stress may lead to poor Wrap quality.Routine upkeep, such as cleaning up the rollers and ensuring they are without debris, can also prevent minor problems from rising. Finally, watching on the maker's performance can help in recognizing patterns that suggest underlying concerns. By resolving these little problems without delay, operators can keep peak functionality and avoid bigger break downs

When to Hire an Expert

Operators might find themselves encountered with concerns that prolong beyond small modifications and routine maintenance. In such situations, recognizing the ideal moment to hire a specialist becomes crucial. It might indicate a deeper mechanical or electrical mistake if the stretch Wrap equipment regularly stops working to run correctly in spite of troubleshooting initiatives. In addition, uncommon sounds, persistent error messages, or failing to Wrap loads safely are indicators that knowledge is needed.Furthermore, if the maker experiences regular failures or if parts are damaged, a professional's treatment is essential to protect against further difficulties. When strange with details fixing methods or when safety dangers are existing, Operators must likewise think about getting aid. Inevitably, timely expert assistance can not just settle complex concerns however also avoid pricey downtime and warranty top performance of the stretch Wrap equipment.

Preventative Maintenance Tips for Stretch Wrap Machines

Frequently Asked Concerns

What Is the Ordinary Lifespan of a Stretch Wrap Equipment?

Can I Use Different Kinds of Stretch Film on My Device?

Different sorts of stretch movie can be utilized on a maker, but compatibility and efficiency might differ - stretch wrap machine repair near me. It's critical to get in touch with the machine specifications and maker guidelines to ensure the very best outcomes and protect against prospective concerns

How Can I Enhance the Performance of My Stretch Wrap Equipment?

To enhance stretch Wrap equipment performance, routine upkeep, optimal movie tension setups, correct positioning, and employee training are important. Furthermore, lessening and updating components downtime through efficient process can greatly enhance total performance and output.

Are There Any Kind Of Specific Brands Known for Dependability?

Several brands are acknowledged for their integrity in stretch Wrap equipments, including Signode, Lantech, and Aetna. Users commonly applaud these suppliers for their toughness, efficiency consistency, and strong customer assistance, improving general operational effectiveness.

What Is the Price Range for Expert Repair Works on Stretch Wrap Machines?

The expense range for specialist repairs on stretch Wrap makers differs substantially, typically in between $150 to $1,500, depending on the intricacy of the problem, parts called for, and the technician's experience involved in the repair work process. The operation of a stretch Wrap equipment involves feeding the film around the product, applying stress, and securing the Wrap, making certain that goods continue to be steady throughout transit.Key components of these machines consist of the film turntable, carriage, and control panel, each playing a crucial duty in the wrapping procedure. Inconsistent film stress can substantially impact the performance of stretch Wrap devices, leading to below average load security and prospective item damages. Regular downtime concerns can signal that a stretch Wrap maker needs immediate fixing. The ordinary life expectancy of a stretch Wrap device typically ranges from 5 to 15 years, depending on usage, maintenance, and the top quality of the device. To improve stretch Wrap equipment efficiency, regular upkeep, ideal movie tension settings, correct alignment, and staff member training are important.